wooden Shipping crates

Whatever the job.

These are wood crates that work until the job is finished.

Wood Crates that carry the machinery, the parts, the instruments and art.

Crates for conveyors and tools, molds and controls.

The cylinders, shafts, pistons and rolls.

The medical equipment, the grandfather clocks, glass tables and trophies

going to Oregon, to Florida and even far overseas.

…and so on, and so-forth…..etc, etc…Crates for anything! You get it?!!

How much, you say? When can you have them? Tomorrow or today?

Now you’re talking!!

Except for the ‘today’ part. You got a little crazy there! Give us a call though, you never know.

Standard industrial shipping crates, built right. Built from quality materials and always screw assembled, our crates are strong, and always do the job. The job of protecting your valuables to their destination.

Certified Export Crates

Certified heat treated international wood shipping crates for overseas shipment.

IPPC stamped and fully ISPM-15 compliant to travel the world, bug free and STRONG.

Don’t know what that’s all about?

Domestic wood shipping crates

Domestic shipping crates are used only for shipment within the United States.

Built right

our Standard wood Crate | higher standards

As you can see, we build shipping crates strong. To work!

Failure is not an option. We want you to come back for more, because our crates did their job for you (and looked darn good doing it).

Here is how we do things here…

Our Crate panel/Wall assemblies

are made from 2x4, or 2x6 framing, and *minimum 1/2” plywood up to 3/4” ply if you really are serious about having a nearly armored crate.

*(Ok, full disclosure: we do use thinner ply SOMETIMES. Only on little crates. For one guy. But that’s only because he MAKES us do it! We have to go to the lumberyard to get it. It’s horrible.)

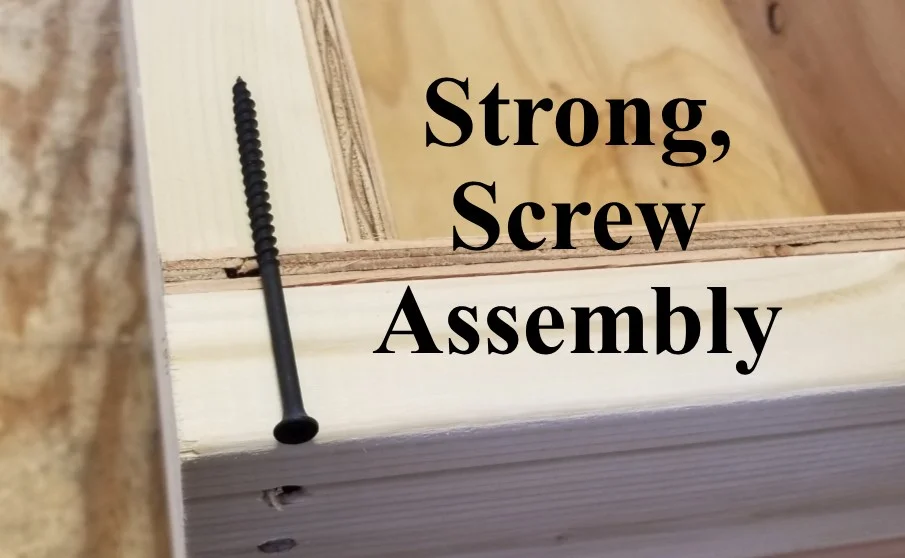

Our crate Box Assemblies

are pre-drilled and then screwed together with 4-inch screws (as shown). They’re not sticking out all over the place either).

Strong and well built. Simple as that.

Common Industry Practice: Nailed or stapled which is certainly faster and a little easier.

(But we prefer very strong.)

Our crate bases/Decks

are made with a minimum 3/4” thick plywood or double 3/4” Ply (1-1/2” Thick) depending on the usage.

For really heavy-duty wood crates we like to use 2x12 (1-1/2” thick planks). They make a really strong deck and give enough material to bolt or screw into. Great for machinery.

Depending on the load, the crate’s deck construction is a critical part of designing a crate for a particular job.

Make it strong = No worries. That’s how we like it.

Our crate skid runners

heavy duty 4x4 skid runners for fork lift and pallet truck access.

Common Industry Practice:

We don’t know WHAT they’re thinking sometimes!

You really want to be able to always fit, not just a fork lift, but pallet trucks also for better handling.

We choose to stick with all of this because it works. The shipping process can be rough and unforgiving at times. It certainly helps to have a good, strong crate protecting your valuable goods.

Remember: Wood Crates are packaging

Like all forms of packaging, they protect, but they also represent the product inside.

So buy good ones. You won’t regret it.

Photo Examples and common uses below

Machinery crates

Electronics crate

Medical Equipment

Motorcycle crates

Scientific Instruments

Speakers and audio equip

Crates for heavy metal parts

Crates for server racks

Bars, shafts, and rolls

Fabricated assemblies

Storage

Industrial crates

Cylinder crates with chocks/cradles

Knocked-down crates (that ship flat and you assemble)

Crates for conveyors and components

The Specialty Crate Factory Difference

Good, clean building materials & pride in our work.

Good materials + Good Work = Good Product

Good product + Good service = Good company to do business with.

(Seems kind of simple really.)

4-inch Screw Assembly

All major components of our industrial crates are pre-drilled and screwed instead of nailed. Its STRONG! It also gives you the ability to disassemble the crate to access your equipment on the crate’s base/skid.

Durable and good looking

Our crates present very well. They do their job and are always strong. No worries for us, or more importantly, you.

That's how we like it, and that’s what you pay for in a Specialty Crate Factory product.

We are confident that you will know that you made a good purchase,

as soon as you see our product.

SCREW ASSEMBLY:

Why do we use 4-Inch screws almost exclusively?

Because it’s faster?…NO

Because it’s cheaper?…NO

Because it’s stronger?…IT SURE IS!

Screw assembling our crates is just a small part of what we do to make a better, stronger wooden shipping crate that always works.

KD = Knocked-down Crates

Crate kits that ship flat and are made to assemble easily.

(We can ship them to you, to your customer, or anywhere.)

A Knocked-down (KD) crate from Specialty Crate Factory is a user friendly crate, in a kit form. It ships flat, it's marked and pre-drilled for easy screw assembly, using 4-inch screws that we supply.

Advantages:

Freight savings - (Especially when shipping multiple knocked-down crates)

Easy loading/securing - Access the skid/pallet from all sides, making it much easier to bolt or tie down your item before assembling the crate box around it.

Easy Assembly - The best part. Our KD crate design really makes it easy for you to assemble in just minutes.

kd crates can be shipped anywhere.

Here’s a scenerio:

Let's say that you have an item in Florida, that needs to be crated, and shipped to you (or even somewhere else). You want it to have an excellent crate to get it there, undamaged.

It’s Easy.

We can ship a good, strong, knocked-down crate to where your item is.

They load it, pack it, easily assemble the crate, and make it ready for shipment. (We make it real easy).

Our carrier (or yours) can pick it up and ship it back to you or wherever else it is needed. With no worries or shopping for a crate company that might do good work.

Contact us to get started…